Markets

01

Medical Technology

In the field of medical technology, both MIM (Metal Injection Molding) and plastic injection molding are suitable for producing small and very small parts used in medical equipment. Both processes offer a range of benefits for the production of medical parts, including the ability to achieve complex product designs and excellent optical characteristics.

MIM processes, in particular, are well-suited for the production of medical parts due to their ability to produce thin-walled and 100% burr-free parts. Alloys such as 316L and 17/4 PH (commonly known as "surgical steel") can be used to meet the highest standards of quality and safety for use in the operating room.

At SIX SIGMA Ltd., we have extensive experience in both MIM and plastic injection molding, and are well-equipped to support the production of high-quality medical parts that meet the strict requirements of the healthcare industry.

02

Automotive

The automotive industry is a major consumer of both metal injection molded (MIM) and plastic injection molded parts. These high strength, high complexity components are used in a range of automotive systems, including gearboxes, turbochargers, locking mechanisms, steering systems, and electronic systems.

At SIX SIGMA Ltd., we have extensive experience in both MIM and plastic injection molding, and are well-equipped to support the production of high-quality automotive parts that meet the demanding requirements of this industry. Our team of skilled professionals and state-of-the-art machinery allow us to deliver high-quality parts with a fast turnaround, ensuring that our customers can bring their products to market quickly and efficiently.

03

Dental Technology

Metal injection molded (MIM) parts have a variety of applications in the dental industry, including the production of complex, shaped components for dental drills and visible parts such as housings that require high standards of visual appearance and product design.

At SIX SIGMA Ltd., we have extensive experience in the production of MIM parts for the dental industry and are well-equipped to support the production of high-quality components that meet the specific requirements of this market. Our team of skilled professionals and state-of-the-art machinery allow us to deliver high-quality parts with a fast turnaround, ensuring that our customers can bring their products to market quickly and efficiently.

04

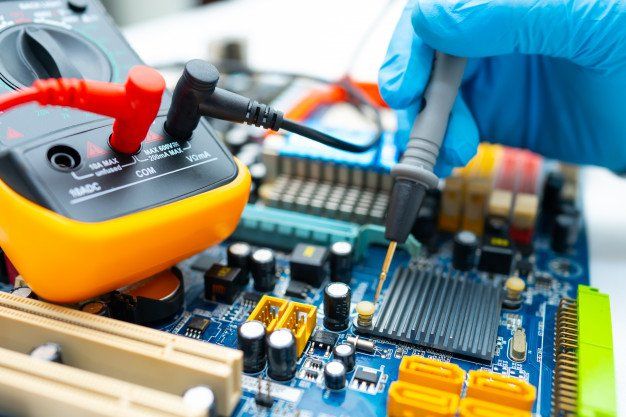

Electrical and Electronic Equipment

MIM is applied in electronics and electric appliances: examples are sensors, plug connectors in kitchenware, as well as components in ovens or dishwashers. They are also found in high-quality electromechanical handyman instruments such as drills, jigsaws, etc. The Metal Injection Molding is perfectly suitable for the series production of thin-walled parts such as sensor housings.

+972-77-3180966

+972-77-6670313

+972-52-5452745

Zeev Jabotinsky St 138

Ramat Gan, Israel, 5260208